The Difference Between Offset and Digital Printing

When you talk to a

printing company do you know whether you want offset or digital printing for

your project, or do you know the difference? Most people think printing is

printing! In this week’s blog, we will explain the difference between these two

printing methods. Hopefully, this information will help you make an easier

decision during your next print project.

Offset Printing

There were two

versions of offset printing developed. In 1875 Robert Marclay of England

developed offset printing to print on tin, while in 1904 Ira Washing Rubel of

the United States developed offset printing to print on paper. Offset printing

uses plates that are generally made from aluminum. The plates are used to

transfer the inked imaged from a plate to a rubber blanket. Then they are

transferred from the rubber blanket to the printing surface. The ink is not

transferred directly onto the paper which is why this process is called offset.

A large reel of paper is fed through a large press machine in several parts.

The paper needs to be continually fed through the machine and the project will

continue to print.

Offset Printing can

have a longer turnaround time due to the setup and maintenance. This style of

printing is usually used for printing larger quantities. There is also a price

break per piece when you print more pieces, which makes offset printing very

cost-effective for a large print job. However, if you have a small print job

the price per piece can be very high with the setup charges. A few more pluses

are you can print with special inks like metallic and Pantone colors. The print

job when completed has amazing detail and color.

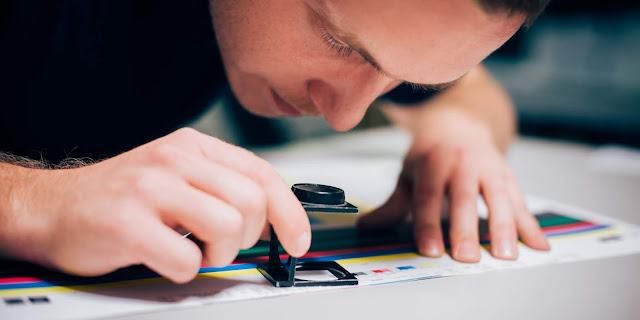

Digital Printing

Digital printing does

not use the plate process instead, toner is used for a laser printer and liquid

ink for an inkjet printer. Digital printed will only print in grayscale or

CMYK. That means if you need a true Pantone color then digital printing will

not be the best option for your project. Digital printing is the way to go if

you have a small print project. There is a quick turnaround time since no

plates will need to be made. You can also have on-demand printing with digital.

Print jobs can be completed quickly so a company doesn’t need to buy more

printed pieces than needed at the time and must store the additional stock.

Another great advantage of digital printing is if you need to add different

coupons codes, names, or addresses onto the image digital printing allows you

to do these actions.

As an overview, both

ways are great for print projects for companies or organizations. The question

is do you need a large number of pieces printed if so, offset printing is the

best option while digital printing wins if you have a small quantity and a

short turnaround time.

At Lake Printing we

have both options available to our customers. Feel free to browse our portfolio

on our website www.LakePrinting.com to see some of the projects we have

completed for our customers. As the printing hub of the Midwest, we would love

to work with your company on your next print project.

You Can Trust Lake Printing for Your Large & Small Print Needs

You Can Trust Lake Printing for Your Large & Small Print Needs

Comments

Post a Comment